Bearing is one of the accessories frequently used in mechanical equipment. We also use bearings in the design of woodworking band saw machine. It is also an important condition to ensure the normal operation of woodworking band saw machine. Bearing should be fixed during work, and should not vibrate back and forth. Some equipment has been used for too long or improperly used, which has caused bearing vibration. Today we will give you a detailed introduction to the classification and principle of bearing vibration.

The vibration of sliding bearings can be divided into two forms according to its mechanism: one is forced vibration, also known as synchronous vibration, which is mainly caused by unbalanced components on the shaft system, misalignment of the coupling, poor installation, etc. The frequency of its vibration is the rotation frequency of the rotor and its multiples. The amplitude of the vibration increases with the increase of the speed before the critical speed of the rotor.

When it exceeds the critical speed, it decreases with the increase of the speed. There is a resonance peak at the critical speed; the other vibration is self-excited vibration, also known as subsynchronous vibration, that is, oil film vortex and oil film oscillation. Its vibration frequency is lower than the rotation frequency of the rotor (about half), and it often occurs suddenly at a certain speed, which is extremely harmful.

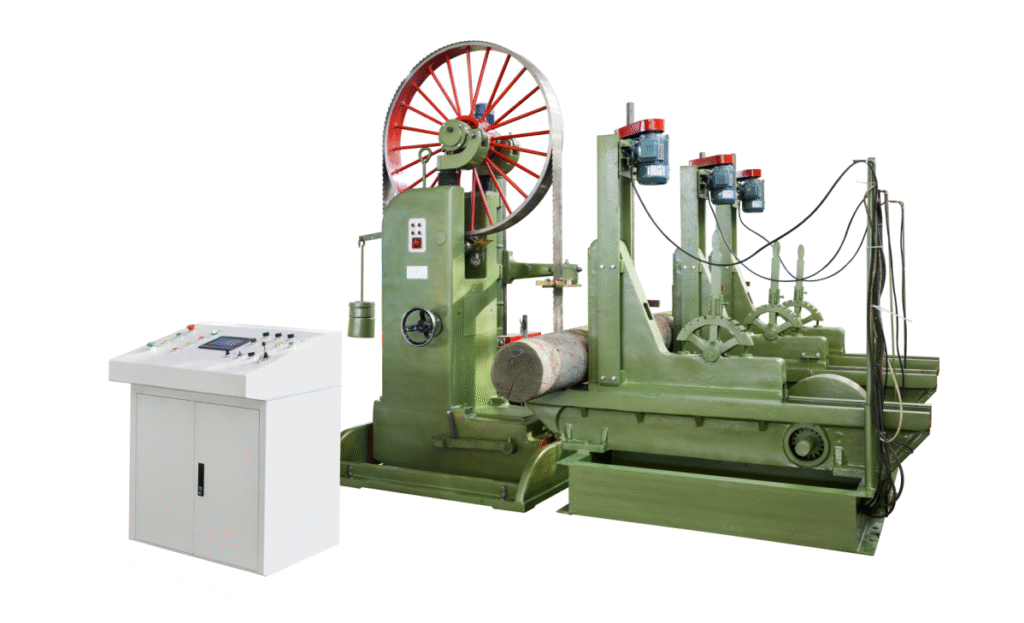

Vertical Wood Bandsaw

Principle of sliding bearing vibration diagnosis: In the design, manufacture and installation of sliding bearings, the issues of reducing forced vibration, avoiding resonance and strengthening the dynamic stability of oil film are generally considered. Therefore, under normal working conditions, the vibration level of lubricated bearings is limited to a lower level. If the vibration of the bearing exceeds this level, it will indicate that it has a certain fault. In addition, vibration is a response of the bearing after being stimulated. According to the frequency retention characteristic principle of linear systems, it is possible to find traces of various vibration sources from the frequency component analysis made on it.