12-60 kw

15-30

80℃

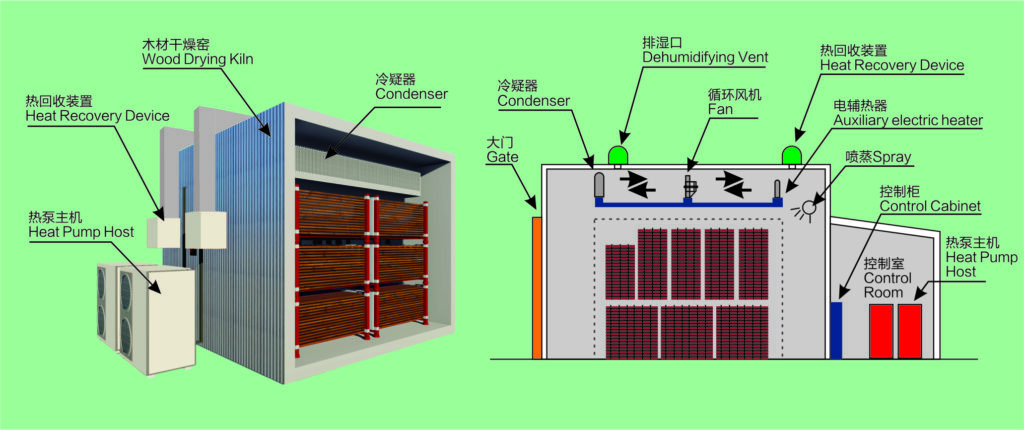

Heat Pump Wood Drying Kiln | MYHR

Price:

NanYang Heat Pump (Air Energy) wood drying kiln is the new-generation environmental protection & energy conservation drying equipment which is developed and manufactured by our company, with technical support provided by Guangzhou Institute of Energy Conversion of Chinese Academy of Sciences. It adopts the heating mode of air energy heat pumps, supplemented by auxiliary electric heating to carry out drying and heat treatment for wood in winter and at night.

|

1-Year Warranty |

Related Parts & Accessories

Use this space to add a short description. It gives enough info to earn a click.

Use this space to add a short description. It gives enough info to earn a click.

Use this space to add a short description. It gives enough info to earn a click.

Use this space to add a short description. It gives enough info to earn a click.

Craft a captivating title for this section to attract your audience.

About This Product

The air energy heat pump unit follows the reverse Carnot principle. Freon vapor is pressurized by the compressor, becomes the high temperature & pressure gas, and then enters the condenser. After the condensation and liquefaction by the refrigerant, the high temperature heat is released to implement heating & drying for the air inside the room, so as to achieve the purpose of wood drying and heat treatment.

Operation video

FAQ

Your woodworking machinery Success Starts with Nanyang

At Nanyang, we strive to provide superior services and solutions that surpass your expectations. Let us find the ideal woodworking machinery solution for your project.